Stemco Inc.

Process Engineer Co-op

2017

Overview

Stemco Inc. produces aftermarket products for the 18-wheeler industry to increase safety, performance and fuel efficiency. As a co-op, I strengthened my skills in lean manufacturing techniques, statistical process control, product design, and systems engineering. I worked on several products ranging throughout the development lifecycle: planning, design, implementation, maintenance, and analysis.

Planning and Design

For a new product (an electronic trailer tracking system) in the conceptual stage, I was involved with the planning of tests and had full responsibility for the mechanical design. The system had to be waterproof, durable, relatively light and easily accessible for maintenance. I modeled the entire system in SolidWorks, purchased components, manufactured the first prototype, and conducted preliminary tests. My design proved effective as it passed all tests.

Final Design of GPS Trailer Tracking System

Implementation and Maintainence

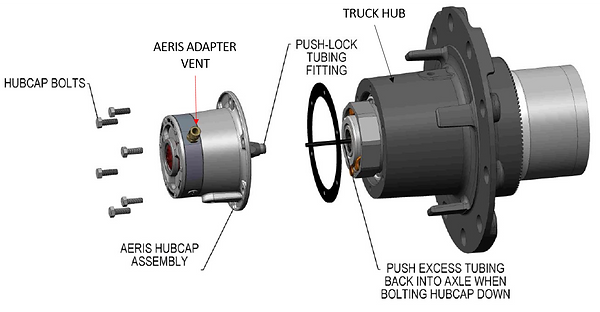

For a new adaptor product (AERIS outlet vent) that was ready for the manufacturing stage, I helped with the implementation and maintenance by constructing a workstation in the most applicable location along the AERIS assembly line. For this new product, I wrote the assembly instructions while utilizing lean manufacturing techniques to standardize, sustain, and organize the process. Furthermore, I ensured that the workflow processes and instructions did not allow misassembly, poor quality construction or human error to be an issue. I performed statistical analysis to eliminate defective hardware, specified torques, and created product holders to establish a workstation that produced flawless components.

The AERIS product is an automatic tire inflation system that is installed onto 18-wheeler hubs. I designed and built the workstation that assembles the adapter vent.

Analysis

For the entire assembly of the TrailerTail product, extensive analysis had to be performed. I helped analyze where nonconformities occurred in the process including the orientation of panels, the selection of fasteners and placement of fasteners. I conducted root cause analysis and drew conclusions backed by statistically obtained data. Through my work I learned how to utilize the Six Sigma methodology of define, measure, analyze, improve and control.

The TrailerTail product is an aerodynamic fairing installed onto the rear ends of semi-trailers to increase fuel efficiency. One of my tasks was revising and improving the instructions, that the shop floor workers followed.